Timber Truss Options

We will build any engineer-approved truss design. The pictures below are some of the most common timber truss designs you will find.

Ready to discuss your project?

Truss Hardware & Connections

Your timber truss hardware can be plain, decorative, etched, painted, or hidden. The choices are completely yours. Whichever you choose, your timber trusses will be strong – built with only the strongest engineer-approved truss hardware.

Wood Finish Options

If no special finish is specified, your timber trusses will be delivered “unfinished”, which is the standard rustic appearance for most timber trusses. You have multiple finishing, chamfer, and staining options for your timber trusses, including:

- Unfinished (the Standard) — Unsanded, natural “rough sawn” look

- Hand Hewn — the antique planed-by-hand look

- Distressed — a rough, aged appearance

- Planed — smooth but unsanded

- Planed and Sanded

- Chamfered or Routed Edges

- Stained and/or Painted — your choice of brand and color

Your timber trusses will be one of the most impressive features – and reliable components – of your project.

Wood Finish Options

If no special finish is specified, your timber trusses will be delivered “unfinished”, which is the standard rustic appearance for most timber trusses. You have multiple finishing, chamfer, and staining options for your timber trusses, including:

- Unfinished (the Standard) — Unsanded, natural “rough sawn” look

- Hand Hewn — the antique planed-by-hand look

- Distressed — a rough, aged appearance

- Planed — smooth but unsanded

- Planed and Sanded

- Chamfered or Routed Edges

- Stained and/or Painted — your choice of brand and color

Your timber trusses will be one of the most impressive features – and reliable components – of your project.

Starting with Ideas

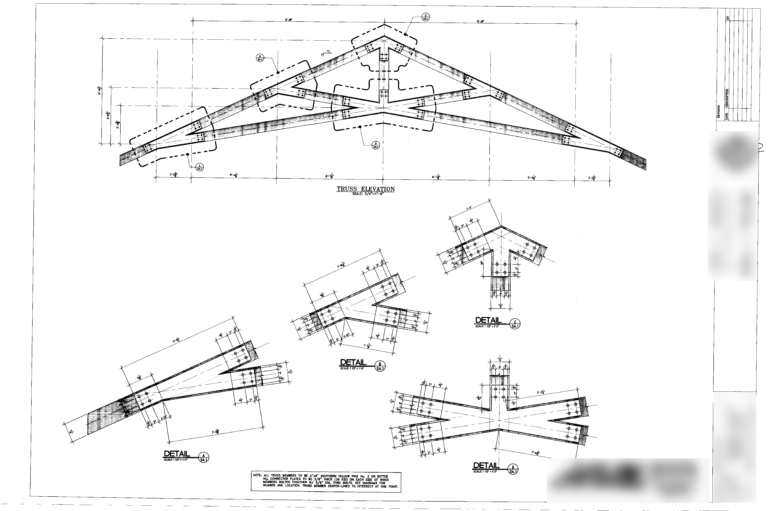

If you are at the beginning stages of your project and need design assistance or want to understand the man timber truss options available, our experienced professionals can help you decide upon the best design for your aesthetic preferences and structural needs.

Additionally, we can connect you with an affordable expert timber truss engineer who will prepare your drawings and approve them for your project.

Design & Engineering

We will accommodate any stage of design. However, if your trusses are engineer-approved and ready for production, send us the drawings and we will begin production upon your approval of our quote.

Any Wood Species & Reclaimed Timbers

Choose from nearly any wood species your design requires.

While most timber trusses are constructed using Douglas Fir or pine timbers, we are happy to accommodate your requests for nearly any wood species such as oak, cedar, greenheart, spruce, cypress, and many more.

We also offer timber trusses made of recycled or reclaimed timbers.

Any Wood Species & Reclaimed Timbers

Choose from nearly any wood species your design requires.

While most timber trusses are constructed using Douglas Fir or pine timbers, we are happy to accommodate your requests for nearly any wood species such as oak, cedar, greenheart, spruce, cypress, and many more.

We also offer timber trusses made of recycled or reclaimed timbers.

Professional Manufacturers

American Timber Truss is a brand of American Pole and Timber, a national supplier of structural and industrial wood products. Since 1993, we have been supplying quality strong, long-lasting custom wood products nationwide.

American Pole and Timber is a member of the Wood Truss Council of American (WTCA) and has supplied beautiful quality timber trusses all over the country for projects of all sizes.

Timber Truss Restoration & Matching

We build timber trusses to match historical or damaged trusses. Common truss restoration projects are churches, school buildings, restaurants, and other historical buildings.

We manage a close relationship with our clients to make sure all project requirements and current building codes are met. From design to finish, we want every little detail to be prefect. For this reason, every restoration or matching project will start with a detailed analysis of the building and its structural needs.

A great example of our expertise in restoring or matching heavy timber trusses is the “Pier 29 Boat House Project”. We rebuilt the Pier 29 Boat Shed (San Francisco, CA) which was damaged by a fire. 15 massive timber trusses were delivered – they matched the historical design, met current load requirements and we finished the entire project in 2 months. Read the full story by SBCA magazine (page 14).

Shipping Your Timber Trusses

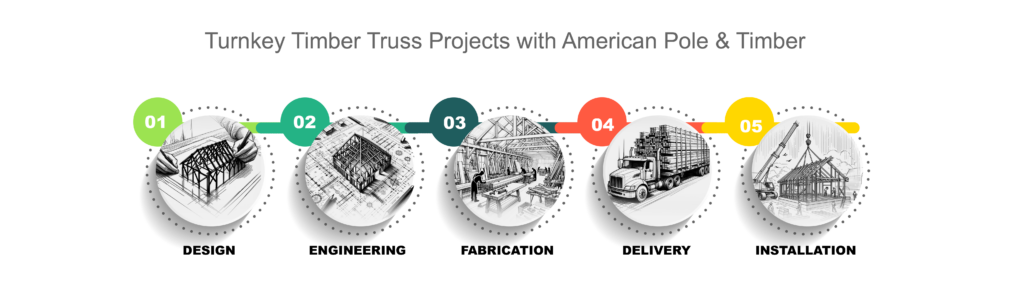

American Timber Truss offers a completely turn-key timber truss experience for your project.

From design through on-site installation, our teams of professionals works with you to turn your timber truss ideas into engineered drawings that we fabricate, deliver, and even install.

The five parts of any timber truss project include:

- Design: from sketches to architectural blueprints

- Engineering: engineer-stamped drawings that are ready to build

- Production/fabrication: expert production by skilled craftsmen

- Delivery: nationwide, with all permits and details handled

- Installation: working with you and your construction team to complete the project

We help you with any or all of these steps to ensure a successful timber truss project that creates the kind of impressive finished project you’re looking for.

Nationwide delivery available for timber trusses of any size.

Some timber trusses are too tall or long to ship assembled. In these cases, we produce and assemble your trusses in our manufacturing facilities as usual. Then, once your giant trusses have passed our quality inspections, we will disassemble them, marking and recording the components throughout the process. The components of your timber trusses will then be shipped to your job site accompanied by at least one of our production professionals and all necessary equipment for the on-site reassembly of your custom trusses.

Our experienced loading and driving staff and contract carriers uphold high standards of safety and inspection requirements. Your custom timber trusses will arrive to your site just as beautiful as when they passed our final inspection.

Size is not an obstacle. Nationwide.

Ready to discuss your project?

to get a quote fast, call our experienced professionals at (866) 909-6845 or contact us online.

We respond quickly and are happy to answer your questions and provide quotes.